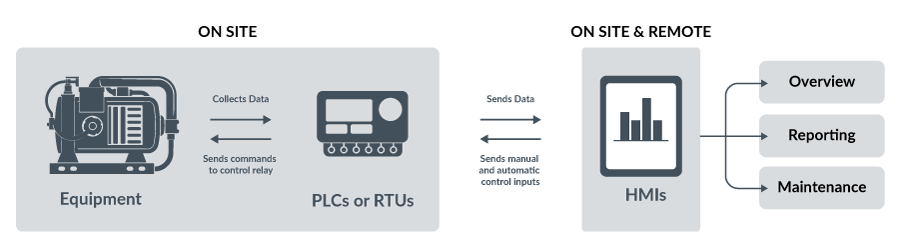

Supervisory Control and Data Acquisition (SCADA) systems are employed to control, monitor, and analyze industrial devices and processes. These systems comprise both software and hardware components, facilitating the collection of data from industrial equipment both remotely and on-site.

What is a SCADA system used for?

The main purpose of a SCADA system is to monitor and control equipment in industrial processes. Thus, SCADA systems are seen almost everywhere. Typically, SCADA systems are used in.

SCADA systems furnish essential insights to key stakeholders, empowering them to enhance industrial plant performance, monitor efficiency, and preempt errors and downtime by leveraging system-generated alerts. In the contemporary industrial landscape, SCADA systems are indispensable for optimizing plant operations, given their efficiency and rapid data collection capabilities, thereby enabling more effective resource allocation across various industries.

A SCADA system interfaces with diverse equipment types, overseeing and regulating a spectrum of functionalities ranging from weather sensors and pumps to power generation and motors, depending on the specific data requirements.

What makes a SCADA system significant?

The significance of a SCADA system stems from its numerous advantages. In essence, SCADA systems facilitate the optimization of production processes and ensure adherence to industry regulations. Moreover, they are often employed for troubleshooting purposes, as effective maintenance is essential for sustaining uninterrupted production flows with minimal errors.

To grasp the importance of a SCADA system fully, it’s crucial to reflect on the era when industrial plants relied on manual monitoring, necessitating personnel to be present on-site during production. This manual oversight incurred significant costs and posed potential dangers to personnel.

However, as industrial facilities expanded and became more geographically dispersed, the imperative for automated solutions became apparent.

Fast forward to the present day, the initial impetus for automation continues to propel SCADA system development forward. By implementing more automated and semi-automated processes, businesses can reallocate resources and achieve long-term cost savings.